Maglev Platform

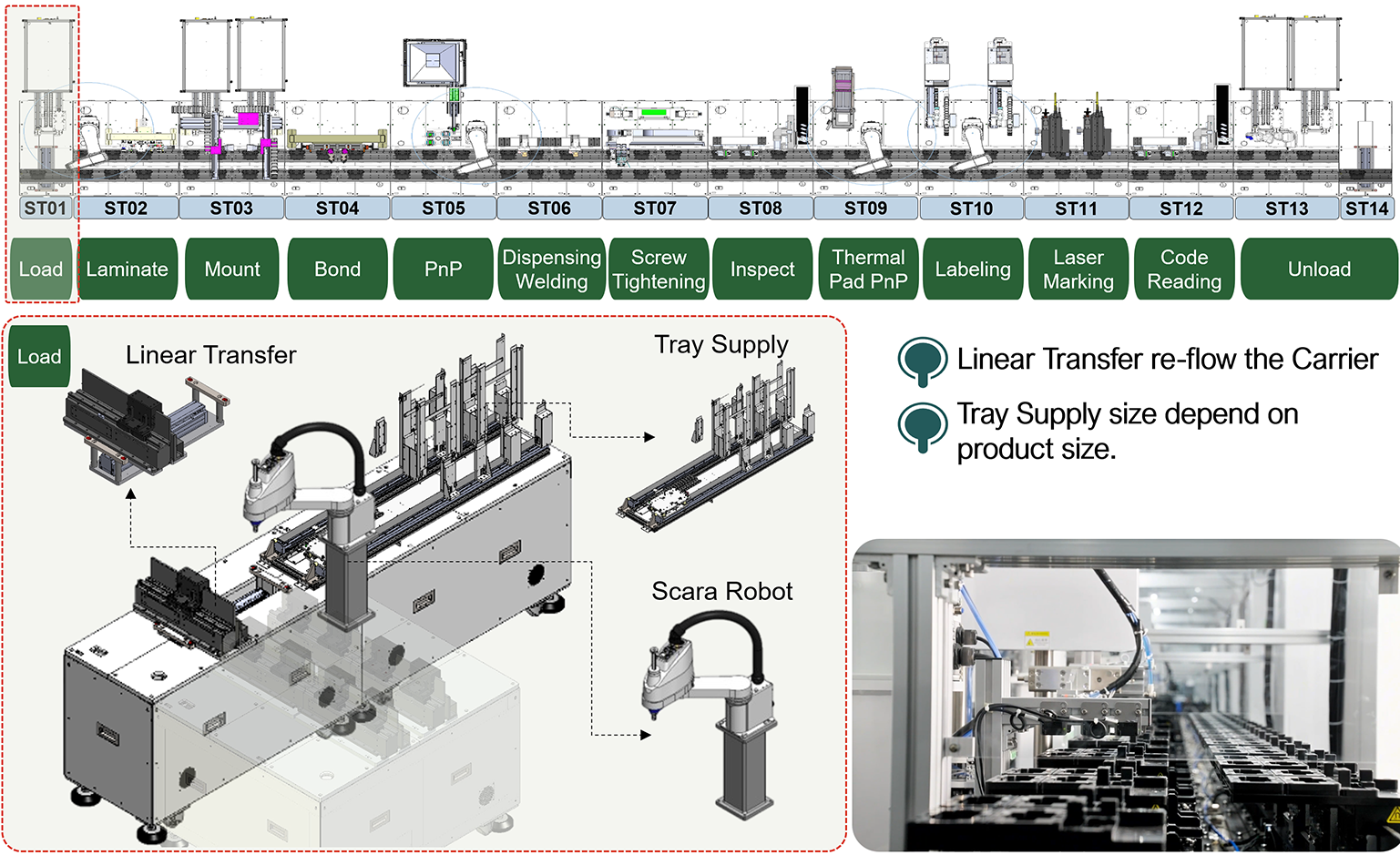

Say goodbye to rigid, maintenance-heavy production lines. The Maglev Platform uses advanced magnetic levitation technology to deliver frictionless, high-speed motion with unmatched precision. Its modular, scalable design adapts effortlessly to evolving manufacturing needs—supporting applications like ACF bonding, laser marking, welding, and more. Built for flexibility, designed for innovation.

The Solution – A Maglev Platform Built for the Future

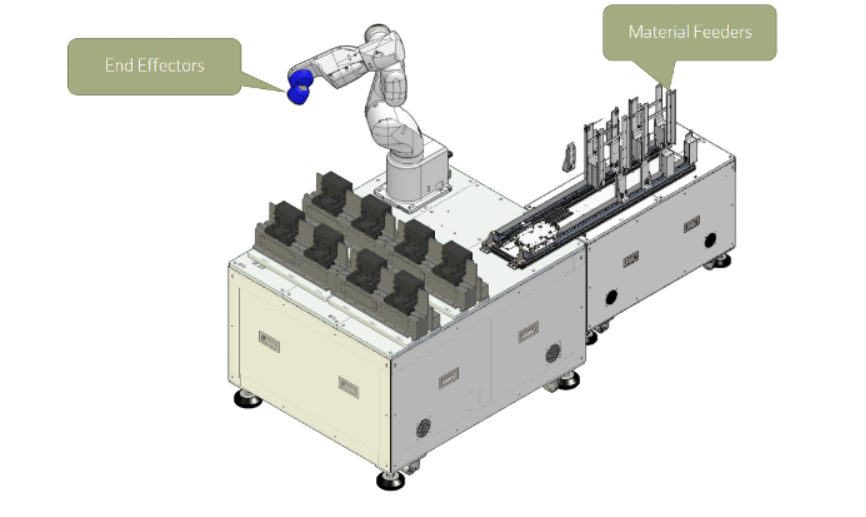

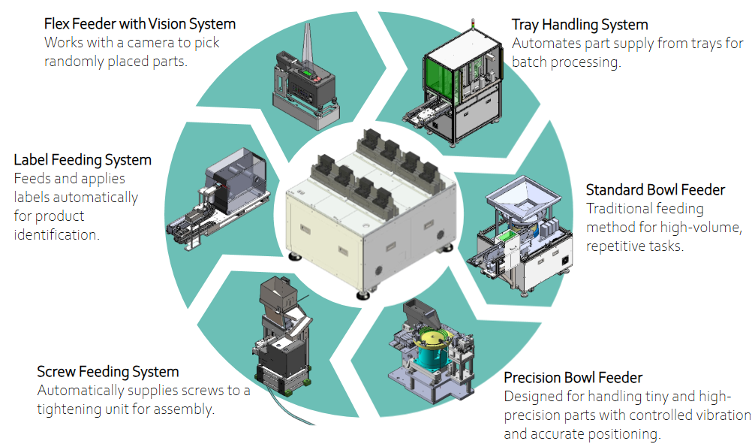

Maglev Transport System

Frictionless, high-speed motion

Modular Design

Use as a standalone or scale up

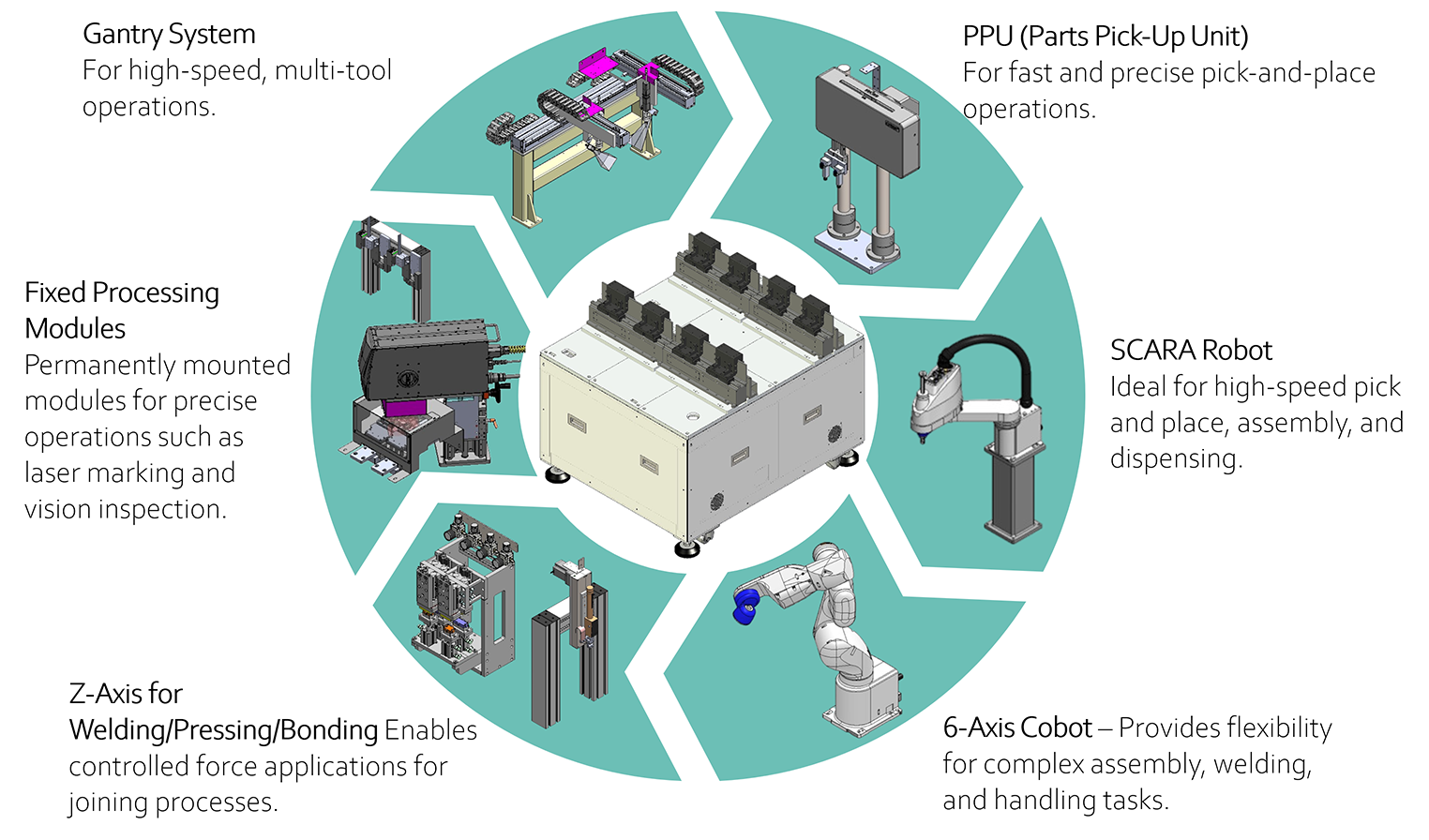

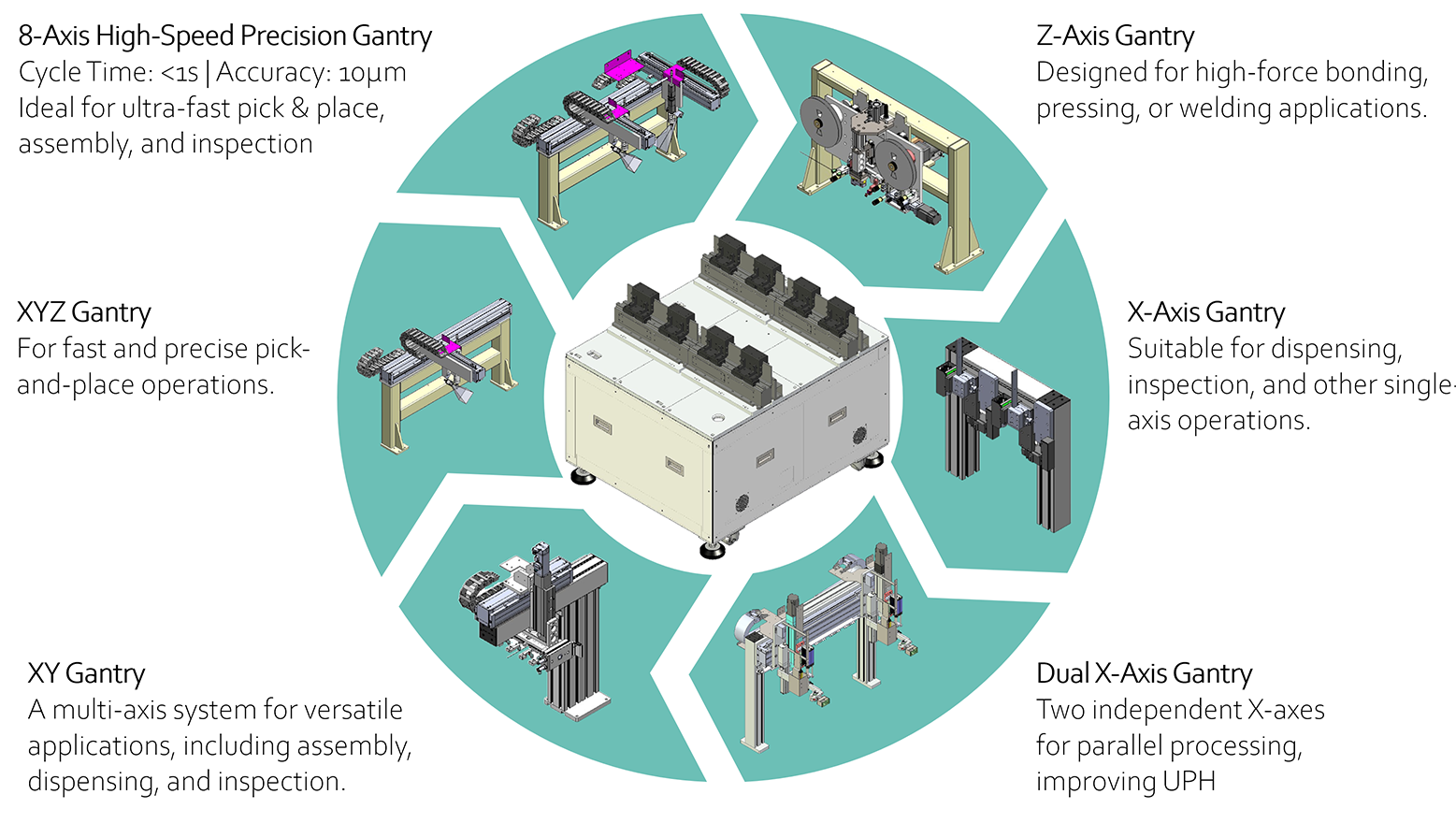

Diverse Applications

Supports ACF bonding, laser marking, welding, etc.

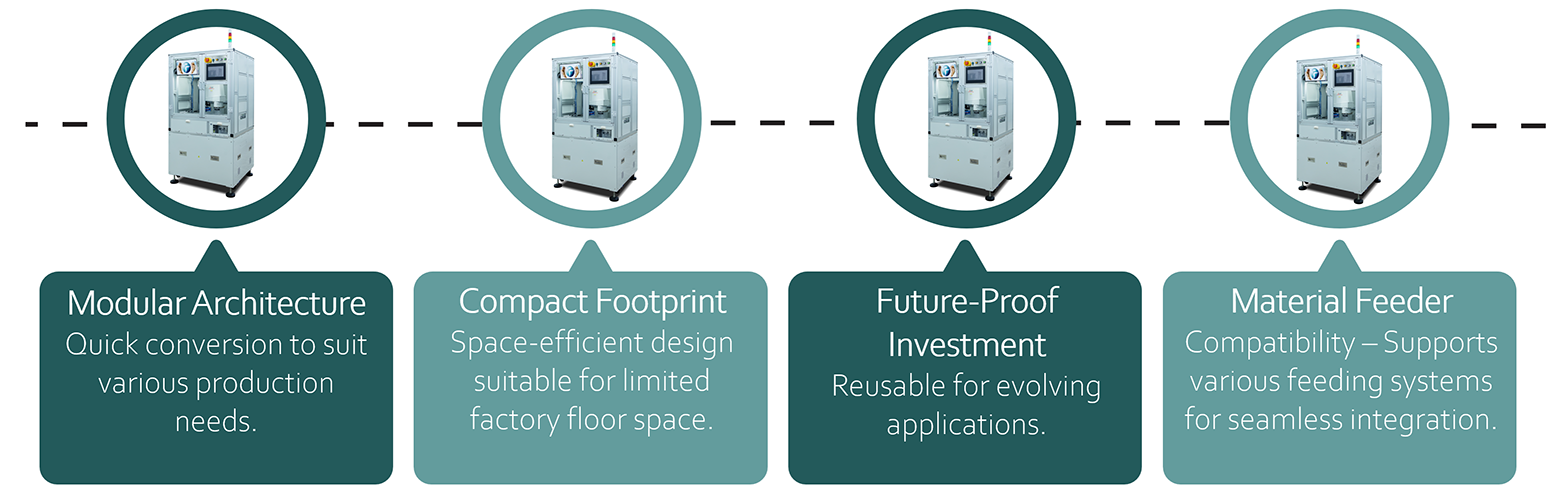

Multiple configurations for different requirements

Multiple configurations for different requirements

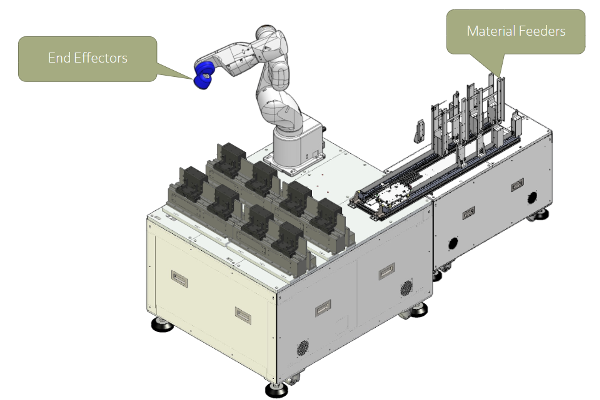

Front type

More Space for End Effectors

Enhanced flexibility for various tasks

Large Material Supply

Such as tray supply at backside

Centre Type

Material supply can be placed at both the front and back of the machine.

Saving space for compact automation applications.

Front and Back

Freeing up more space in the middle for end-effectors without material supply needs.

Top and Bottom

More Space for End Effectors

Enhanced flexibility for various tasks

Large Material Supply

Such as tray supply at backside

Would like to learn more?

E-mail us: ieu@ito-group.com