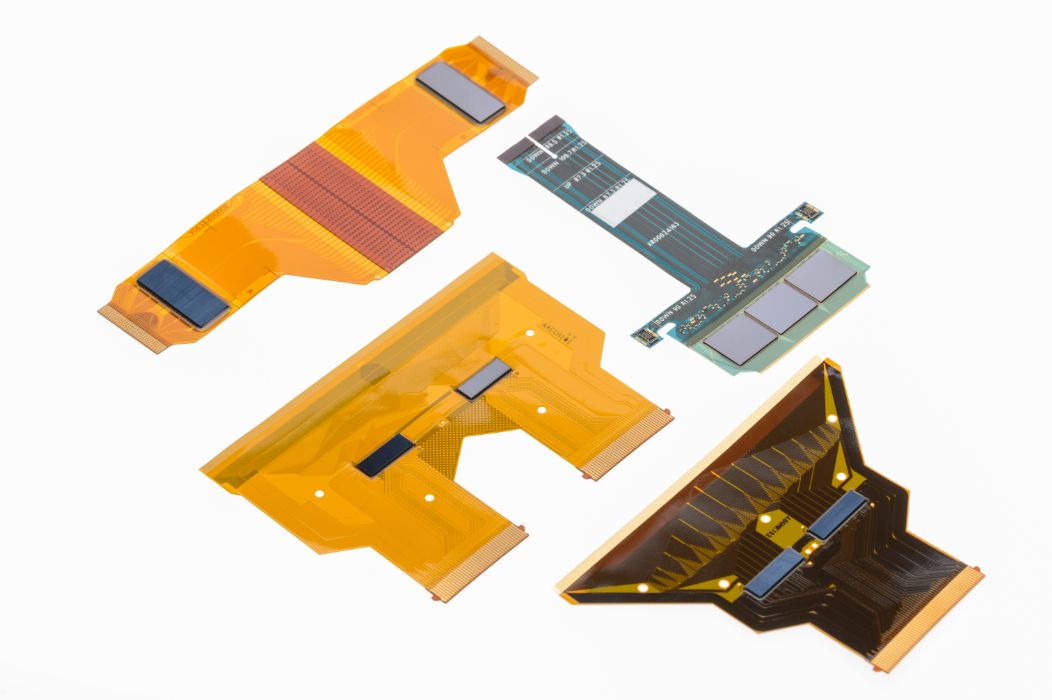

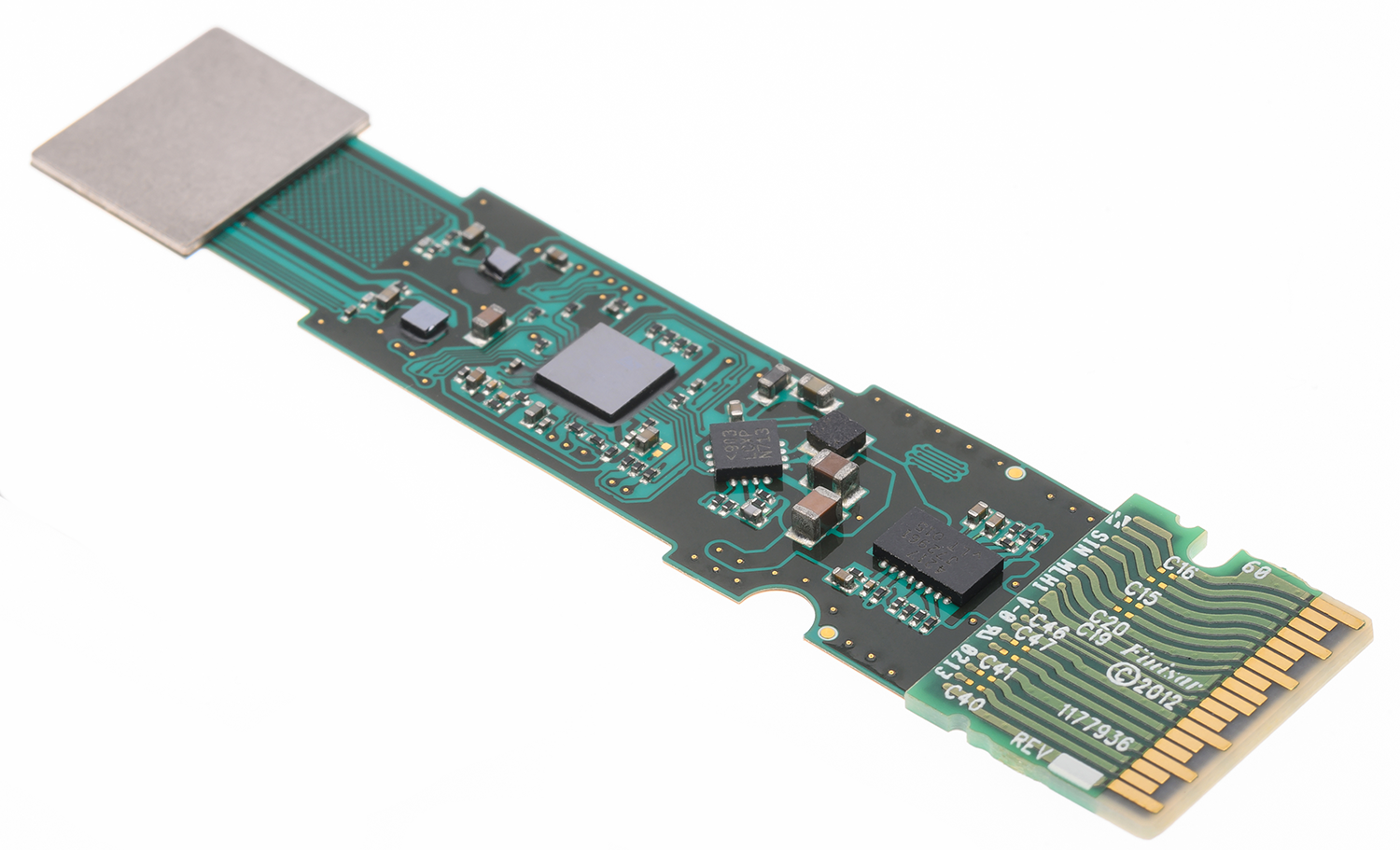

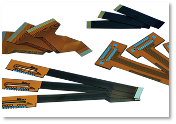

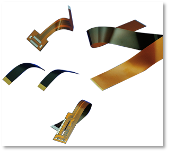

Flexible Printed Circuits (FPCs)

Unleash design freedom with Ito Europe’s Flexible Printed Circuits — ultra-thin, durable, and precision-built to meet your needs from prototype to high-volume production, with expert support every step of the way.

What are Flexible Printed Circuits (FPCs)

FPC’s are lightweight, thin, and bendable electronic circuits made by printing conductive traces onto flexible substrates like polyimide or polyester. Unlike traditional rigid PCBs, FPCs can bend, fold, and twist, making them ideal for compact and dynamic applications.

Key Components of FPCs

Substrate

Usually polyimide (PI) or polyester (PET), providing flexibility and heat resistance.

Conductive Traces

Typically made of copper, silver, or carbon.

Adhesive Layers

Bind the circuit components together while maintaining flexibility.

Protective Coverlay

Shields the circuit from external damage, moisture, and contaminants.

When it comes to FPC’s – these and more is what Ito Europe offers

Access to state-of-the-art technology even at low volume

Excellent product quality and highest reliability

Minimum Order Quantity flexibility as products scale from prototype to mass-production

Cooperative product design and best-practice consulting

Reliable supply and long-term customer/supplier relationship

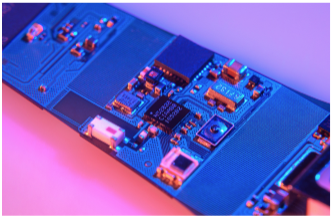

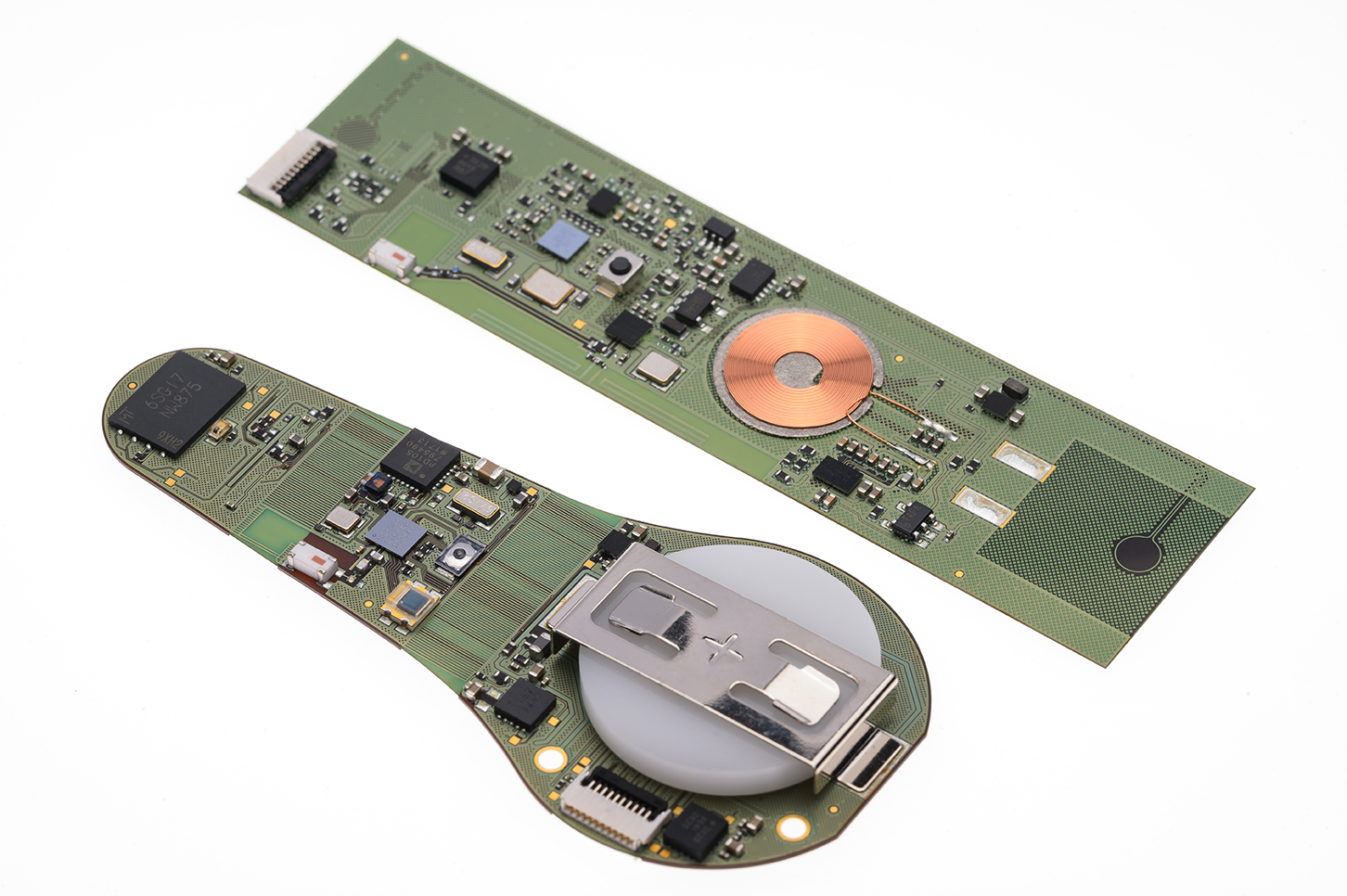

Full Service Circuit Board Design

Ito Europe works with own partners and clients to create the optimal board design which fulfils all requirements while respecting the design rules

Ito Europe can provide a variety of custom flexible circuit solutions

Single-sided FPC

One conductive layer, simple design, cost-effective.

Double-sided FPC

Conductive layers on both sides, allows for more complex circuits.

Multilayer FPC

Stacks multiple flexible layers, offering higher circuit density.

Pitches down to 30 μm (subtractive process). Up to 8-layer flexible circuits. Variety of assembly technologies. Quick deliveries from a single unit.

Applications Examples

Would like to learn more?

E-mail us: ieu@ito-group.com