Atmospheric Plasma Cleaning

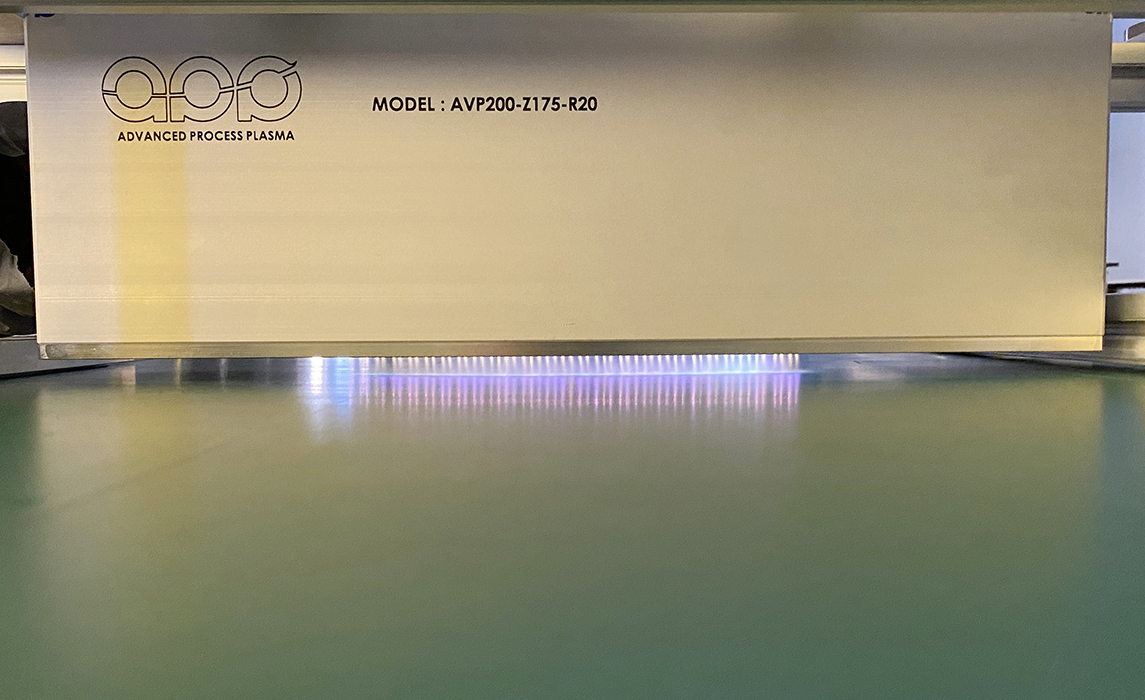

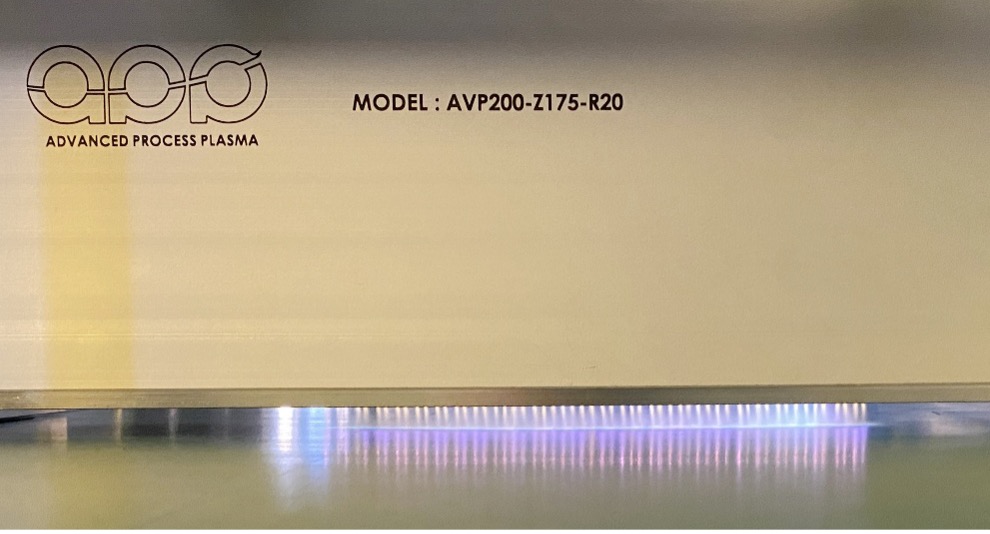

Atmospheric plasma cleaning is a dry, environmentally friendly surface treatment process that removes contaminants, oxides, and organic residues from materials using ionized gas (plasma) at atmospheric pressure. Unlike vacuum plasma, it does not require a controlled chamber, making it faster and more adaptable for Electronics and PCB Manufacturing, Automotive and Aerospace, Medical devices and biotechnnology.

How It Works

A high-energy electrical discharge ionizes a gas (e.g., air, nitrogen, or argon), creating a reactive plasma.

The plasma interacts with the surface, breaking down and removing contaminants like oils, dust, and oxidation layers.

The process enhances adhesion, cleanliness, and wettability for subsequent bonding, coating, or soldering steps.

Benefits of Atmospheric Plasma Cleaning

Effective Contaminant Removal

Removes organic residues, oxides, oils, and dust at a microscopic level.

Eco-Friendly

Reduces or eliminates the need for chemical solvents, making it a greener alternative.

Improved Adhesion

Enhances bonding for coatings, adhesives, and paints by modifying surface energy.

Non-Destructive

Works gently on delicate materials without causing mechanical damage.

Increased Process Efficiency

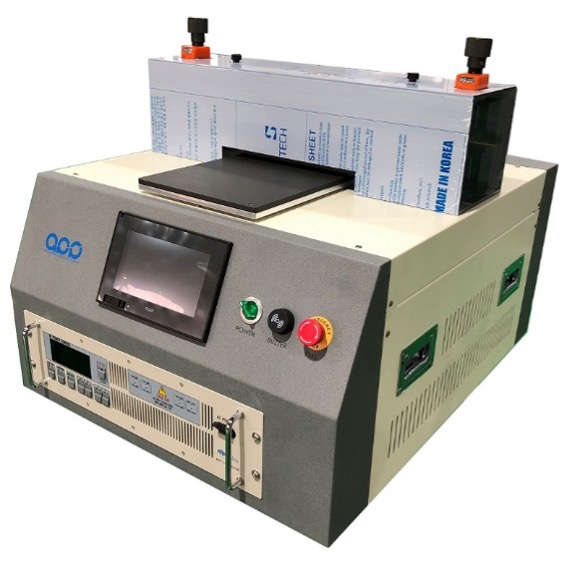

Offers rapid cleaning and is easy to integrate into automated production lines.

Features of Atmospheric Plasma Cleaning

Process Type

Dry, gas-based process

Cleaning Mechanism

Plasma removes contaminants via ionization and oxidation

Environmental Impact

Eco-friendly, no hazardous waste

Surface Compatibility

Works on metals, plastics, glass, composites

Adhesion Improvement

Enhances surface energy for better bonding

Drying Time

No drying needed

Process Speed

Fast and efficient

Cost Efficiency

Lower operational costs in long term

Automation Capability

Easily integrated into production lines

Safety

No harmful chemicals or fumes

Target Industries & Applications for Atmospheric Plasma Cleaning

Atmospheric plasma cleaning is widely used across industries that require high precision, strong adhesion, and contamination-free surfaces. Here are some key industries and applications:

Electronics & PCB Manufacturing

– Cleaning PCBs before soldering to remove oxides and residues

– Enhancing adhesion of conformal coatings and encapsulants

– Surface activation for improved bonding of electronic components

Benefits: Prevents defects like delamination, poor solder joints, and weak adhesion of coatings.

Automotive & Aerospace

– Pre-treatment of plastic and metal components before painting or coating

– Improving adhesion for structural bonding and sealing applications

– Cleaning of connectors and sensors before assembly

Benefits: Enhances long-term durability, ensures strong adhesive bonding, and eliminates surface contaminants without damaging delicate parts.

Medical Devices & Biotechnology

– Cleaning and activating surfaces of implants, syringes, catheters, and diagnostic devices

– Improving bonding of coatings for biocompatibility

– Removing organic contaminants from precision components

Benefits: Ensures high levels of cleanliness for medical-grade materials and enhances the performance of coatings and adhesives.

Ito Europe offers various atmospheric equipment solutions.

Would like to learn more?

E-mail us: ieu@ito-group.com